- Company

Menu

MenuTradition and innovation go hand in hand at Hauhinco. Founded in 1908 in

Sprockhövel, Germany in the cradle of Ruhr mining, Hauhinco has remained

true to its roots – up to the present time. For over 100 years, the company

has adapted to many changes in structure and circumstances and continually

brought new, innovative products onto the market. This experience makes

Hauhinco unique in the market place. - Solutions

Unsere technische Abteilung entwickelt kundenspezifische Wasserhydraulik-Lösungen und setzt mit ausgeprägtem Projekt Know-How, Kundenwünsche und Anforderungen exakt um.

Hauhinco is represented in a large number of industries with water hydraulic components and fluid system solutions.

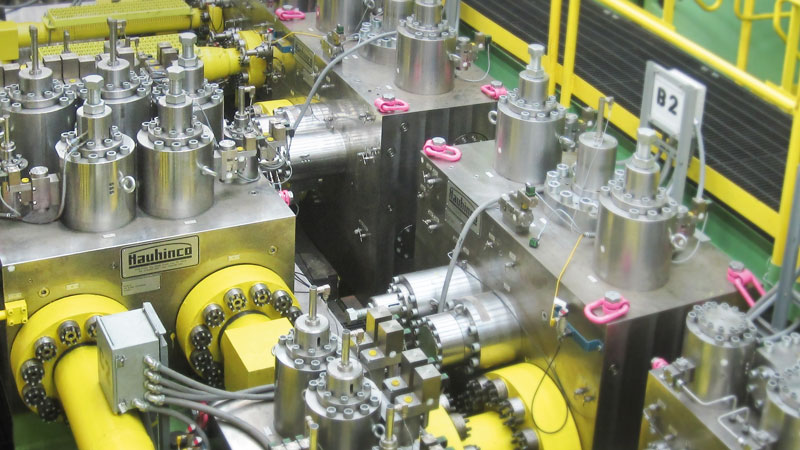

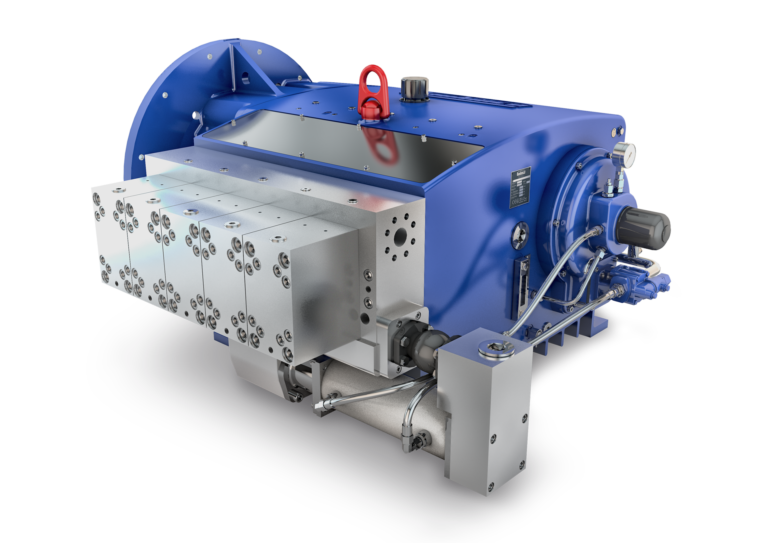

Whether high pressure pump station or water spray pump station, with or without water treatment, we manufacture certified pump systems with all the necessary approvals for underground mines all over the world.

- Products

The increasing quality requirements of steel, stainless steel, copper and forged products simultaneously increase the requirements for the descaling process.

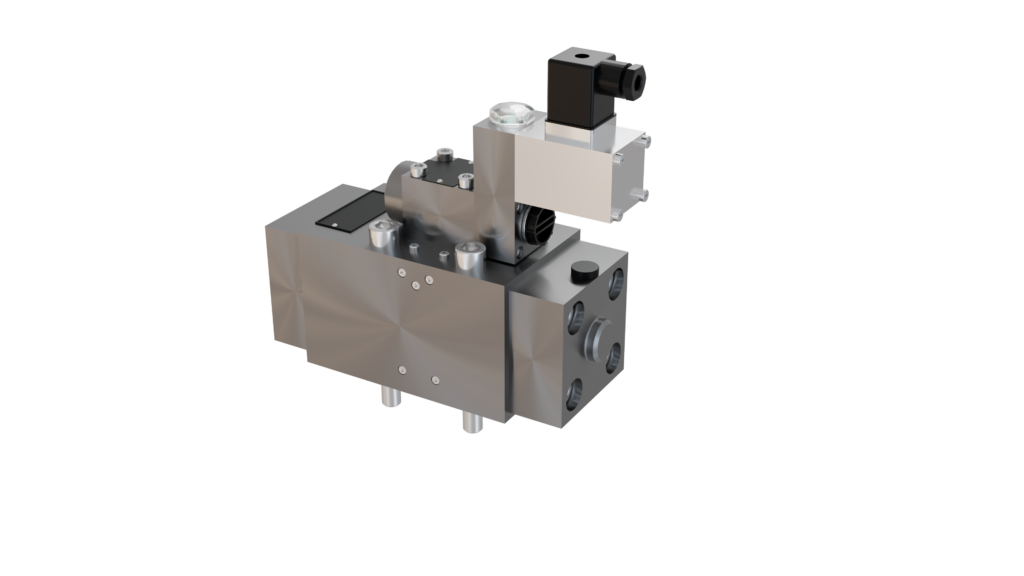

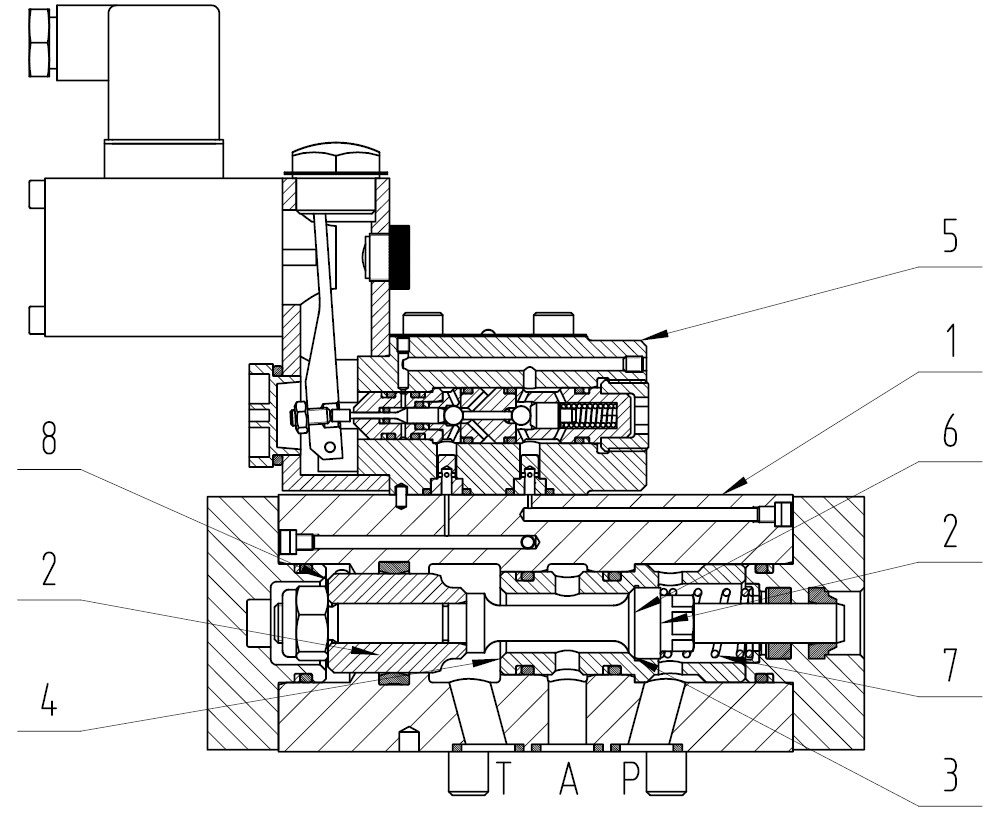

Along with control blocks (controls, manifolds), control technology and modular fluid systems, valves are among the most important components in water hydraulic installations.

- Service

Menu

MenuThe Hauhinco Service supports our customers all over the world with the commissioning, maintenance and repair of our high pressure plunger pumps, valves and water hydraulic systems as well as with the spare part identification and supply.

- Careers

Menu

MenuHauhinco is a successful, medium-sized family business with a long tradition. Today the company is a leading provider in the area of water hydraulic applications. Our high pressure plunger pumps, valves and systems are used in underground in underground mining and industry all over the world. Our employees are the key to success.

- Contact

Hauhinco has contact persons and representatives in all Mining and Industrial regions of the world.

Africa, Australia, Bosnia and Herzegowina, Bulgaria, China, Croatia, England, Finland, France, Germany, India, Iran, The Netherlands, Norway, Poland, Russia, Switzerland, Slovenia, Spain, Turkey, Ukraine, USA

- Downloadcenter

English