Hydromechanical Descaling

Turnkey Descaling Systems

Hydromechanical Descaling

There are no compromises to German quality

The increasing quality requirements of steel, stainless steel, copper and forged products simultaneously increase the requirements for the descaling process.

In order to meet these stringent requirements today and in the future, hydromechanical descaling is widely used in the production of high quality hot-rolling products.

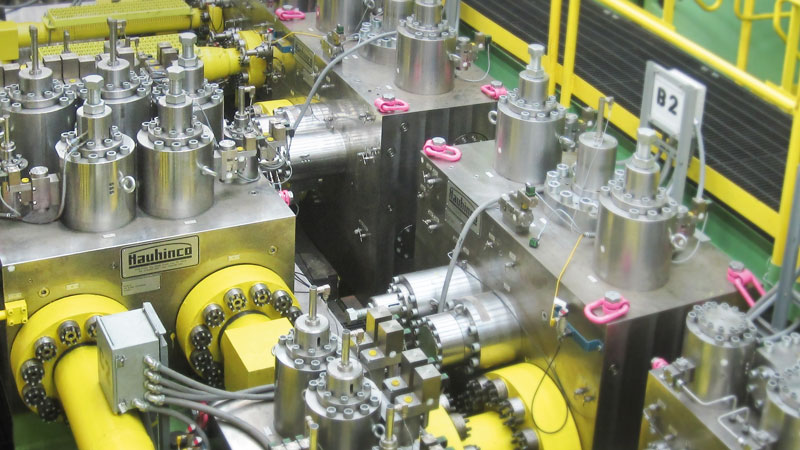

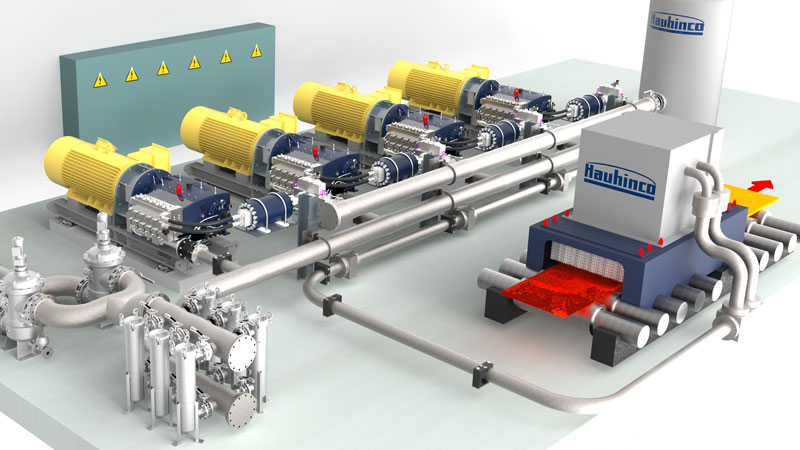

Hauhinco develops turnkey hydromechanical descaling systems for scale-free results of hot-rolled products. Many decades of practical work experience by our employees in descaling as well as in water hydraulics in the field of pump-, valve- and fluid system-technology in a large number of applications provide the basis for the development of our customized solutions.

Efficient descaling systems from a single source

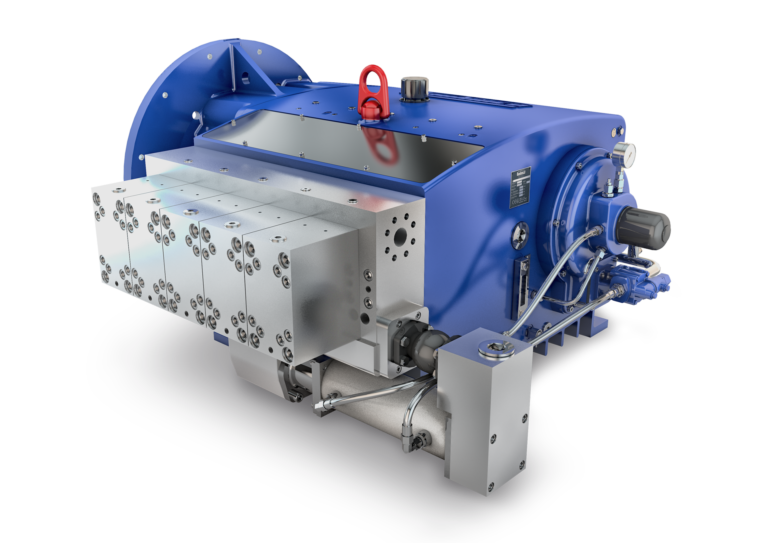

At Hauhinco the high pressure pumps, valves, descaling valves and components as well as the entire descaling system engineering come from a single source. We know the particularities involved in the descaling of rings, blocks, rods and pipes, slabs and billets as well as sectional steels and the related high quality requirements for their production. In addition to the high quality, Hauhinco provides for a large number of additional advantages and savings with an efficient and intelligent system design as well as by low maintenance and operating costs.

Hydromechanical descaling systems that meet the most stringent requirements

The increasing quality requirements for steel products and forged products also entail more stringent requirements for the descaling process. In order to meet these stringent requirements today and in future, hydro-mechanical descaling is the suitable method for use in the production of high quality hot-rolling products. Hauhinco develops descaling systems and solutions ranging from stand-alone high-pressure plunger pumps to valves and complete turnkey, energy-efficient descaling systems with automation and workpiece manipulation. Our portfolio includes the descaling of large-scale continuous products as well as the automated multi-version descaling of high-alloyed special products.

Reduction in maintenance costs

For system operators, efficient maintenance is a significant competitive factor. A maintenance measure is always efficient if it is carried out at defined intervals and at an optimum point in time. Maintenance on all Hauhinco products and systems can be executed easily and fast during shutdowns, e.g. during summer or winter shutdowns.

Additionally, the design of the Hauhinco descaling system does not include any pressure accumulators. By not using pressure accumulators, annual maintenance costs can be reduced by up to 50%. The advanced technological development state of our descaling systems provides the basis for the production of high-quality products and the long-term reduction in life-cycle costs. This sustainably assures the competitiveness of your company.

HAUHINCO develops and provides the complete package which makes the well-planned step to hydro-mechanical descaling as easy as a walk in the park:

- Filter technology

- Pressure supply

- Nozzle bar

- Descaler / Descaling box

- Automation

- High pressure piping made of stainless material (1.4571/1.4541)

Four advantages of turnkey Hauhinco descaling systems

Direct supply

Direct supply enables a consistent operating pressure and consequently leads to optimum and stable descaling results with a reduction in rejects of up to 3 to 5 %

Customized solutions

Individual solutions re-using existing or adapted products. Resulting in precise engineering solutions and best-value

Easy to maintain

Each of the spray valves can be exchanged separately, resulting in reduced downtimes and stocking of spares

Quick commissioning

Modular installation: Typical Installation and commissioning inside of one week, that means implementation is possible during shutdown without any long-lasting break; then very short preventive maintenance and assembly time