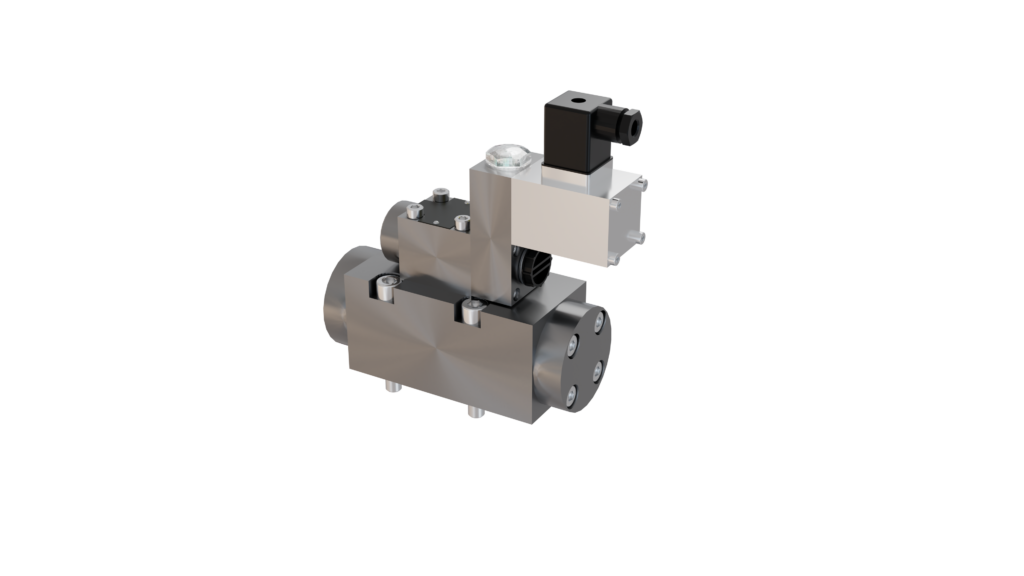

General | |

| Weight | 7,0kg |

| Installation position | any |

| Ambient temperature | -10 to 50°C (hydraulic fluids, heed standard requirements) |

Material Valve parts

Material Seals | Stainless steel, except for the electromagnet

NBR, PTFE |

Hydraulic | |

| Hydraulic pressure connector P, X | <= 500bar, see Order information |

| Hydraulic pressure connector A | <=P <= 500bar, see Order information |

| Hydraulic pressure connector T, Y | <= 10bar |

| Direction of flow | P->A, A->T |

Pressure fluid

- Medium - Quality

- Medium - Temperature range

- min filter fineness connector P, A, T | Water, HFA

see Hauhinco media requirement, water, HFA

5 - 40°C

Filter fineness 25µm |

Pressure fluid

- Medium - Temperature range

- Medium - Quality

- Viscosity | Mineral oil HLP according to DIN51624-2

5 to 50°C

Cleanliness class -/19/16 according to ISO 4406

0,6 bis 100 mm²/s |

| Use of other pressure fl uids on request. | |

Electric | |

Magnet

- Voltage

- Operating time

- Degree of protection acc. to EN60529

- max. switching rate |

24 VDC

see Order information

100% OT

IP65

0,5 Hz |

Included in the scope of supply | |

| Mounting screws of the valve | Cheese-head screw |

Cable socket of the valve solenoid

- Supply voltage 24 VDC | according to DIN 43650 – type of design A

max. 100 VA |

Menu

Menu Menu

Menu中文 (中国)